For Tissue e Paper

Dust removal system

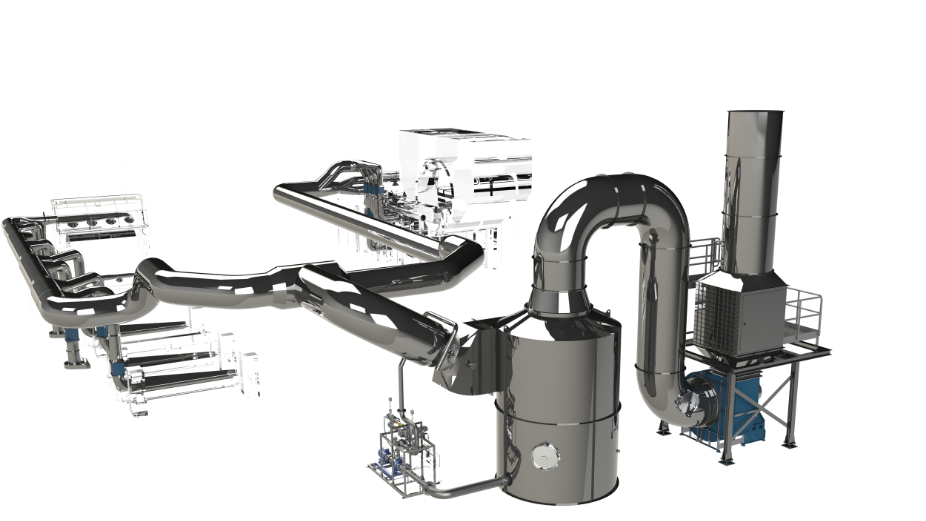

Mevas provides high-efficiency dust removal systems for Tissue machines, rewinders and converting

Mevas provides high-efficiency dust removal systems for Tissue machines, rewinders and converting

The dust removal systems is fundamental, especially in the paper industry , to reduce fire hazards, limit machine components wear and improve environmental quality for the operators.

Thanks to the innovative technology of the concentrate wet abatement, Mevas guarantees a significant removal of the dust deriving from the different production stages.

Furthermore, Mevas dust removal systems ensure a substantial ambient conditions improvement for the operators, in the face of reduced water consumption.

The complete customization of suction boxes and system configuration (composed by watering section, separation and extraction) implies an easy adaptation to the most varied facility layouts.

The Mevas dust extraction system is fully customizable in terms of size, number and conformation of suction boxes, materials used and optional accessories.In addition, it succeeds in ensuring optimal capture at low power consumption; it is adaptable to all local and regional specifications in terms of dust concentration, noise impact and water consumption.In addition, it is equipped with Mevas industry 4.0 ready control PLC.

Mevas dust removal system guartantees a consistent reduction of fire hazards compared to the traditional dry systems, thanks to the complete dust abatement in the central unit through an apparatus of spray nozzles.

The significant decrease of the dust in the production environment involves less wear of internal and external machine components, guaranteeing greater durability and performance over the years. The opportunity of remote assistance (Industry 4.0 Ready) helps to find out and solve immediately the eventual failure, eliminating breakdowns risk.

The automatic discharge of dust removed prevents the operator to face all the routine maintenance issues typical of dry removal systems. At the same time, the use of high-quality materials and components limites the system maintenace costs, increasing the runnability and the working life

Whether it’s a new facility or an old system revamping, Mevas identifies the winning solution in terms of layout impact and technical features, according to client’s requirements and needs.

Contact us

Turn to your paper partner: our team is

always ready to answer promptly your question.

A reliable and performing boiler room is a must in all branches of paper industry.

Read moreIn the Paper industry, an accurate sizing of the Steam & Condensate system and all the main components is fundamental.

Read moreMevas realizes complete high-efficiency drying systems for the paper industry, from the design to the field start-up

Read moreMevas provides high-efficiency dust removal systems for Tissue machines, rewinders and converting

Read moreMevas designs and realises turn-key mist removal systems for the paper industry.

Read moreA well balanced hall ventilation is closely related to the machine characteristics and crucial to avoid manufacturing inefficiencies and structural issues.

Read more