For Tissue e Paper

Hood and air system.

Mevas realizes complete high-efficiency drying systems for the paper industry, from the design to the field start-up.

Mevas realizes complete high-efficiency drying systems for the paper industry, from the design to the field start-up.

Mevas Air System, basing on the most advanced engineering technologies, is actually the state-of-the-art drying systems on the market.

The perfect synergy between the Yankee Hood and the Air System involves an extremely accurate overall balance, empowering the entire drying performance.

Stratoflame by Mevas is the only burner conceived and realized to accomplish the needs of the paper industry in terms of performance, energy saving and emissions.

The fluid dynamics innovations, the use of special steels and the provision for the hydrogen combustion make Stratoflame a real unicum in the paper industry.

While working with the minimum air excess, Stratoflame guarantees a substantial energy saving, accompanied by very low emissions and a long working life.

The special constructive geometry patent by Mevas allows Stratoflame to work with the minimum combustion air excess, producing an immediate and substantial energy saving thanks to the lower gas consumption.

Stratoflame has been developed through CFD simulation, basing on the typical parameters of a Tissue Air System in order to totally accomplish the requirements and the peculiarities of the paper production process. With an eye on the future, Mevas burner has been already tested for a 100% hydrogen combustion.

Stratoflame has been conceived with a modular design in order to be suitable for the most varied Air System configurations, without affecting its top performance. The special cone geometry patent by Mevas generates a controlled air swirl which causes an optimal combustion and consequently ultra-low CO and NOx emissions

Stratoflame-HE ℗ is the latest evolution of the Mevas burner to meet the energy and sustainability challenges of the paper industry. Stratoflame Hybrid Electric combines the electrical component with the innovative features typical of the Mevas burner, making it adaptable to any future energy scenario.

Stratoflame HE, thanks to its absolute adaptability in terms of combustion perfromance and insertion in the Air System, strongly favors energy diversification in the paper mill. The alternation or modulation of the available fuels, together with the possibility of integration with electricity, guarantee a 5.0 burner, capable of pandering to the progressive energy evolution of the paper industry.

Stratoflame is extremely energy flexible as it has been tested with the most common fuels or blends, with no loss of performance or worsening of emissions. With Stratoflame-E, Mevas is able to supplement electricity with available fuel, from minimal percentages up to full electric.

The electrical power that can be integrated into the combustion system is fully customizable, since it is based on the series installation of individual electrical modules, variable in shape and location in the Air System. The electrical component can be sized according to available power or layout requirements (available space, location, conformation, etc.).

Stratoflame-HE is the suitable burner for environmental and energy sustainability, reducing production costs while substantially reducing CO2 emissions through the use of green energy.

Cerebro is the computational software developed by Mevas for the Air System sizing and the optimization

Cerebro, through a complex cross-analysis of Temperature, Moisture content and Impingement Speed, calculates the optimal settings to maintain the current production standards at the lowest possible cost.

Cerebro highlights the best point in the Iso-Drying Graphic (optimum) ensuring the optimal Air System setting for any kind of production. Following the trend emerged from the optimum calculation, you can achieve the lowest energy cost possible €/ton, without changes in terms of production characteristics and volumes.

Cerebro is totally molded on client’s machine, basing on peculiarities and production charcteristics typical of each paper mill. All the machine data are directly extrapolated from the DCS and integrated with the additional field instruments required. Consequently, every Cerebro configuration is unique and perfectly tailored on client’s needs.

Mevas has elaborated a user-friendly interface which helps the operator to easily follow the optimization trend by comparing historical data, current settings and the potential optimum point for any specific production. Cerebro is equipped with a differentiated user level in order to restrict access to the sensitive data of the company.

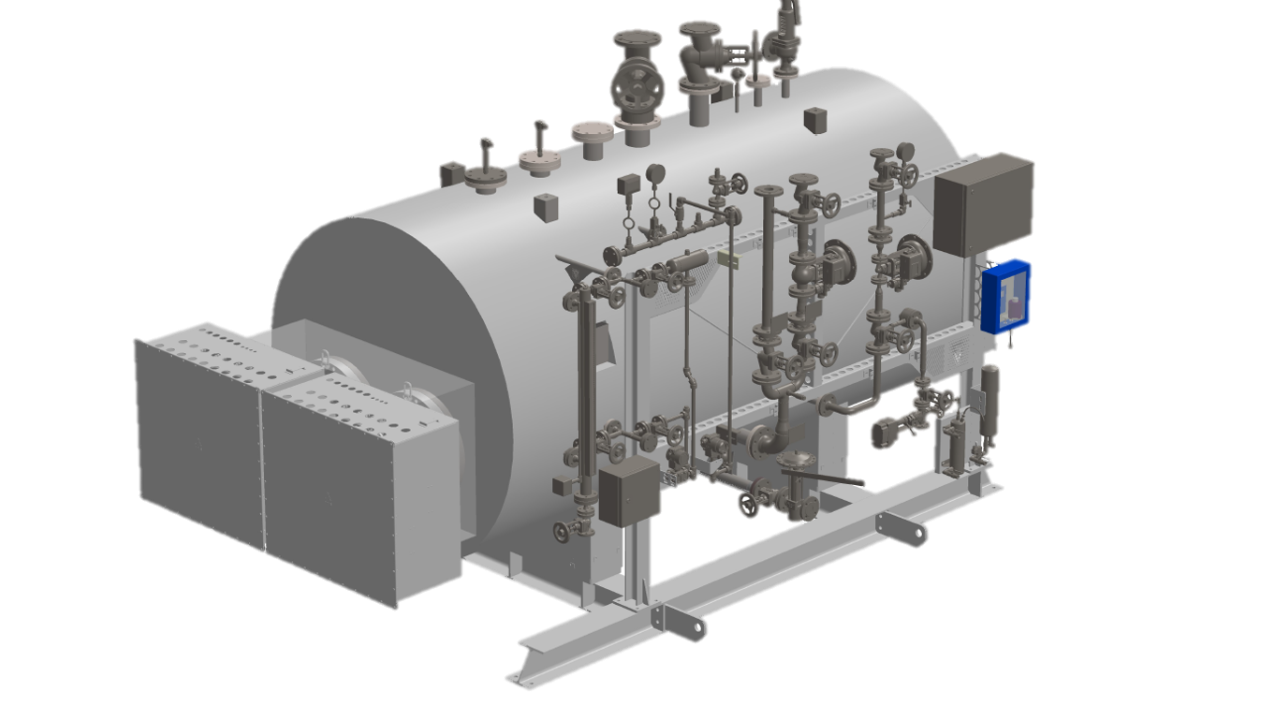

Steam Pack is the pioneering steam generator from exhaust, conceived and patent by Mevas.

Mevas Steam Pack, produces saturated steam through the related exchange battery by using the heat of the exhaust fumes and the condensate from the Yankee pressure tank. The newly generated steam is separated in the dedicated high-pressure tank and then used to supply the Yankee aftwer an accurate adjustment.

Mevas Steam Pack, produces saturated high-pressure steam suitable for the process, by using the energy contained in the exhaust flow which would otherwise be wasted. _SP guarantees an exceptional energy saving given by the part of saturated steam recovered from the exhaust. The _SP newly generated steam is returned in the process leading to a lower gas consumption from the boiler.

Steam Pack relies upon an automatic control system which utilizes sensors and modulating valves of higher quality to ensure performance and long life of the components. The steam generated is monitored and accounted in real-time in order to make the troubleshooting as quick as possible and act promptly through the encrypted remote connection.

_SP, thanks to its slim design and the skid structure, is perfectly adaptable to any facility configuration with a very low impact on the mill layout. The ease of installation reduces assembly and maintenance costs, especially considering facilities with tight spaces available.

The Steam Pack Electric is Mevas' innovative system for producing saturated steam through the modulable combination of heat recovered from the fumes and electricity.

The Steam Pack Electric is Mevas' revolutionary product for meeting the energy, environmental and production sustainability challenges of the paper industry. Steam production from fuman recovery is integrated with electricity from modulating heating elements, making the Steam Pack E an effective system to drive the energy transition and reduction of CO2 emissions in the paper mill.

SP-E Mevas produces high-pressure saturated steam by harnessing the energy contained in the fumane and subsequently supplementing it with the input of electricity through modulating resistors. This combination reduces or eliminates the use of fossil fuels.

SP-E Mevas produces high-pressure saturated steam by harnessing the energy contained in the fumane and subsequently supplementing it with the input of electricity through modulating resistors. This combination reduces or eliminates the use of fossil fuels.

In addition to the double contactor, which provides a safety level up to SIL3, there are 4 thermostats of in case of surface overtemperature of the resistors. In addition, the SP-E switchboard is equipped with a control unit with Bus communication for monitoring and recording energy data.

Whether it’s a new facility or an old apparatus revamping, Mevas identifies the winning solution in terms of layout impact and technical features of the Air System, according to client’s requirements and needs.

Contact usMevas Air System, through the accurate sizing in the design stage and construction elements of higher quality, ensures blowing and extraction uniformity, besides the removal of all the moisture spots which arise during the production stages.

The enclosed insulated hood system designed and realized by Mevas, by respecting the zero point, minimizes the thermal bridges with major benefits in terms of energy saving, components and structures wear and production environment livability for the operators.

Mevas' winning approach implies a comprehensive study including steam system and aerothermal system of the machine, since optimal drying performance cannot split these two areas.In addition, the correct design of the hood in both its construction and energy characteristics positively influences production quality by avoiding moisture pockets and internal dripping phenomena that can damage or deteriorate the sheet.

The precise sizing of Hood and Air System generates a substantial thermal insulation of the paper machine, avoiding imbalances in pressure, temperature and moisture with a significant overall energy saving. For the machine energy optimization, Mevas includes the installation of heat recovery units for the Pocket or the Hall Ventilation.

Blowing and extraction are optimized thanks to the main perimeter duct and the high-efficiency boxes Air Lamina Injector which are designed to eliminate the moisture spots arising during the production stages. The continuous monitoring of temperature , pressure and moisture ensures the maintaining of the right manufacturing conditions.

The perfect balance between the machine and the adjacent spaces reduces the diffusion of the drying mists in the hall, extending the life of the external components, the near systems and the hood structural elements, besides avoiding condensation phenomena in the mill.

Whether it’s a new facility or an old apparatus revamping, Mevas identifies the winning solution in terms of layout impact and technical features of the Air System, according to client’s requirements and needs.

Contact us

Turn to your paper partner: our team is

always ready to answer promptly your question.

A reliable and performing boiler room is a must in all branches of paper industry.

Read moreIn the Paper industry, an accurate sizing of the Steam & Condensate system and all the main components is fundamental.

Read moreMevas realizes complete high-efficiency drying systems for the paper industry, from the design to the field start-up

Read moreMevas provides high-efficiency dust removal systems for Tissue machines, rewinders and converting

Read moreMevas designs and realises turn-key mist removal systems for the paper industry.

Read moreA well balanced hall ventilation is closely related to the machine characteristics and crucial to avoid manufacturing inefficiencies and structural issues.

Read more